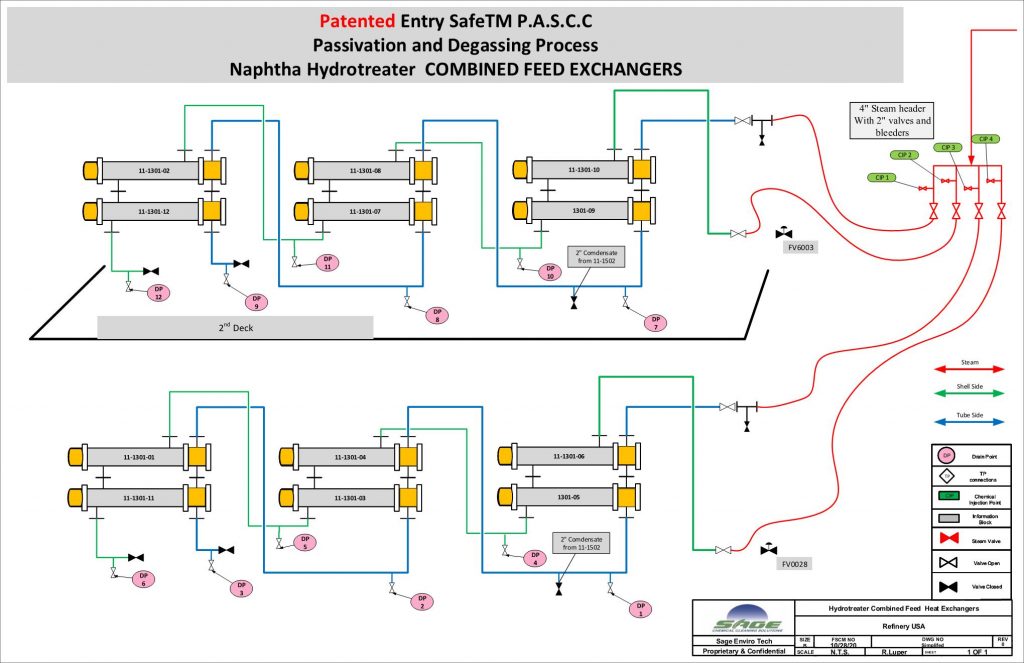

At Sage Chemical Cleaning Solutions and Decontamination, we are always looking for solutions to decrease our client’s downtime, increase equipment turnover, and not jeopardize our commitment to protect the environment and personnel safety. Many years of research and development have gone into our services. One example of our research and development is the degassing process and use of Entry Safe ™ P.A.S.C.C. (Polythionic Acid Stress Corrosion Cracking) neutralizer.

Entry Safe ™ P.A.S.C.C. plus degassing formula is an exceptionally high performing chemical and process. The process is used at low concentrations to neutralize/degass refinery equipment that experience chloride cracking (polythionic acid formations). Our formula is used in accordance with the NACE standard, SP0170-2012, for the protection of austenitic stainless steel from polythionic acid stress corrosion cracking during equipment exposure to atmospheric conditions.

The patented process is a one-step program. Further, this process is delivered either as a liquid wash or steam vapor phase depending on your equipment design. The final result is that all targeted equipment is not only NEUTRALIZED but also concurrently removes hydrocarbons, LELs, VOCs and Benzene.The waste solution is generally drained into the unit’s oily water sewer for disposal.

Contact a Sage Chemical Cleaning Solutions and Decontamination expert today! To learn more, please call (833)SAGECLN (833)724-3256 or email us at info@sageccs.com.